2.1.4.1Operational Excellence Function

Management Approach

The scope of SBM Offshore’s Operational Excellence Function is to continually oversee core business activities across their lifecycle (from ’Win’ to Execute’ to ’Operate’) and drive SBM Offshore towards high performance, not only from an economic perspective (covered in section 2.1.6) but also through effective risk management, quality/compliance assurance and continuous improvement.

Among the various aspects of Operational Excellence within SBM Offshore, are the following main themes:

- Leadership and Culture: with the ambition to ’Target Excellence’, the complementary Life365 and Right365 programs frame the development of SBM Offshore’s leadership and culture, focusing on the combined objectives of ’No Harm, No Defects, No Leaks’.

- Operational governance: as described in section 3.8.

- Process Safety Management and Risk Management: described in sections 2.1.2 and 3.6.1 respectively.

- Management Review: building on International Standards such as ISO 9001, SBM Offshore has established a set of internal processes ensuring a regular, structured review of its management and control framework against its latest strategy and actual performance.

- Knowledge Management and Continuous Improvement: ensuring that lessons are effectively learned, also building on internal knowledge and experience as well as industry best practices.

- New ways of working under Fast4Ward® and Digitalization – explained in sections Fast4Ward® and 2.1.8.

- Quality and Regulatory Management described below.

Quality & Regulatory Management

SBM Offshore is committed to performing its business in full compliance with all applicable laws and regulations and to delivering products and services meeting all related regulatory requirements, as well as any applicable specifications and requirements imposed by relevant stakeholders.

As part of the Operational Excellence organization, the combined Quality & Regulatory Management function is dedicated to ensuring that such objectives are consistently met in SBM Offshore’s core business, notably through:

- Promoting a quality and compliance culture.

- Maintaining SBM Offshore’s certification to the ISO 9001:2015 Standard.

- Providing systematic identification of applicable regulatory requirements and ensuring their implementation.

- Ensuring that conformity, compliance and acceptance of SBM Offshore’s products and services are effectively achieved and maintained.

- Supporting continuous improvement of business processes and ways of working.

Regarding Operational Excellence & Quality overall, SBM Offshore is focused on reducing and mitigating risks to its business activities, notably:

- Significant risks related to project execution, process safety, human capital and changes in laws and regulations − as mentioned in section 1.4.

- Other operational risks such as loss of integrity of aging assets, loss of certificate of class and disruption to the supply chain.

2021 performance

SBM Offshore is proud to note the following key achievements:

- Active promotion of ’Target Excellence’ principles through diverse initiatives.

- Maintenance of SBM Offshore’s ISO 9001:2015 certification, including scope extension to the Terminal systems activity.

- Further development of an integrated Product and Regulatory Assurance approach, building notably on project/operational experience to upgrade our processes including ’Cost of Non-Quality’ processes.

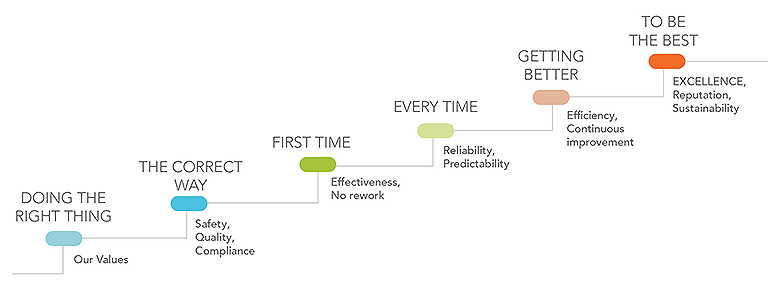

- Strengthening of the Right365 program under the banner of ’Target Excellence’, with a specific focus on ’Doing the Right Thing, Right First Time’ with the deployment of mandatory Quality Rules e-Learnings for project personnel.

- Development of a new version of SBM Offshore’s enterprise management system GEMS (’Sapphire project’) to align GEMS structure and content with the new ways of working brought by the Enterprise Resource Planning project ’Integra’.

- Lessons Learned Initiatives performed to improve SBM Offshore’s projects and operations.

- Development of a digital version of technical standards (GTS) that will be available through a Requirement Management Software in 2022.

- Effective use of independent third parties for inspection, verification and assurance services related to Execute and Operate activities.

Importantly, all company offshore facilities were duly accepted by all relevant authorities and regulators, with all related permits, licenses, authorizations, notifications and certificates duly granted and kept valid. Offshore facilities have also remained in class at all times as required from both statutory and insurance perspectives. No significant operational fine was paid in 2021.

FUTURE

For 2022, SBM Offshore will be focusing on the following subjects:

- Process Safety Management objectives as described in section 2.1.2.

- Further development of a Knowledge Management framework to grow in-house expertise and support continuous improvement.

- Roll out of a new version of GEMS, ’Sapphire’.

- Deployment of digital version of the GTS.

- Development and deployment of digital solutions supporting Operational Excellence, including a tool to execute technical assurance.

- Development of technical assurance framework beyond engineering phase.

- Transition from Cost-of-Non-Quality to Quality incidents to improve effectiveness and prevent reoccurrences.

- Maintenance of an effective regulatory watch and interface with regulators.