2.1.8Digitalization

MANAGEMENT APPROACH

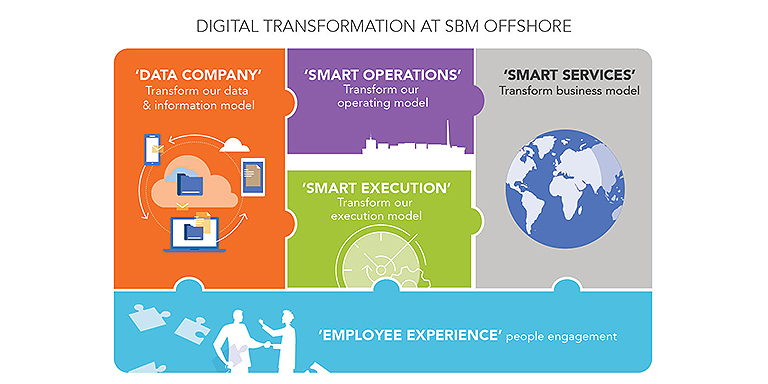

The purpose of digitalization is to create value: better safety, emission reduction, cost savings or new revenues, for instance. With digitalization, SBM Offshore creates value through optimization of existing processes, transformation of SBM Offshore’s core products and ways of working or creation of new digital services.

SBM Offshore has reinforced its organization and governance, with the creation of a Transformation Office, which provides the guidance, the framework and the support for SBM Offshore to become more digital. The Transformation Office is under the responsibility of the CEO. Digital solutions are brought to market through the Services function, described in section 1.3.3.

2021 PERFORMANCE

In 2021, SBM Offshore has continued to gain technical insight and has positioned digitalization as a key enabler of SBM Offshore’s strategy and value platforms. SBM Offshore uses Digitalization to:

- Improve safety and enable remote control of SBM Offshore’s assets, thanks to IoT (the ‘Internet of Things’), the OIPOC (Operational Intelligence & Performance Optimization Center) or remote assistance tools.

- Reduce CO2 emissions through improved work processes. For instance, Process Stability digital tools allow the reduction of equipment trips which, in turn, reduces emissions, thus contributing to the emissionZERO® program.

- The launch of the first pilot of the new ERP system, to further increase lifecycle value from its projects and operations through end-to-end data connection.

- Ease collaboration and allow SBMers to work together, regardless of their locations, through tools such as Microsoft Teams or collaborative platforms (e.g. the Engineering Collaborative Environment).

- Make better decisions through business intelligence software such as Power BI, enabling better insight of historical data.

- Boost learning and working experience through mobile apps or augmented reality.

- Optimize assets operations and utilize data science and artificial intelligence for predictive maintenance. This has led to operating cost savings in the FPSOs that SBM Offshore services on behalf of its clients.

- Optimize project execution through end-to-end process platforms (Integra), or visualization and planning of work fronts at the construction yards. This includes 3D Construction and Work Fronts Management or ‘Robotic Process Automation’ (RPA) technologies that allow the automation of repetitive tasks.

- Create new opportunities and diversify SBM Offshore’s revenues by delivering high-value digital services to customers through Smart Services, a New Energy & Services Product Line.

- 18% increase in the cumulative number of operational signals, compared with 2020, to above 120k. This includes key process indicators such as pressure, temperature, etc. − stored and leveraged for remote monitoring of rotating equipment and process systems, troubleshooting and machine learning (see below graph).

future

New technologies are rapidly evolving. SBM Offshore will benefit from these new technologies and will develop the skills and capacity necessary to adopt them.

Digitalization requires adopting an end-to-end approach and assessing value throughout the product lifecycle, with further roll out of the ERP system contributing. It also requires building foundational capabilities that support the entire structure. Hence, SBM Offshore will reinforce its organization with the creation of a central Data Office, responsible for the definition and governance of the Data Model. SBM Offshore will rationalize its digital applications landscape and develop a data platform enabling access and integration of data generated from multiple digital applications. This data platform will become the enabler of the Lifecycle Digital Twin and of the customer portal for new digital services.